Gallery

Overview

GROW is an FDA-certified food processing facility and incubator space designed to assist food and product-based manufacturers with training, processing, packaging, and distribution of their products.

Reasons to Invest

- GROW is the first and best option for food producers of all types to utilize an FDA certified kitchen to effectively launch and grow their business.

- Multiple revenue sources and the founders’ extensive experience in the industry greatly enhance its growth potential.

- GROW is uniquely positioned with it’s first mover advantage to create a large and consistent revenue stream.

- Knowledgable founders bring regional expertise and connections that are key to success in the Bahamas.

- Demand for FDA certified products is exploding with the increase in cruise ship traffic, and the desire for the region to reduce imports and become more self sufficient

The Challenge

- The lack of an FDA certified kitchen limits the growth potential of Bahamian food producers and continues to make the region dependent on imports.

- Lack of certified infrastructure limits revenue potential for restauranteurs and small business entrepreneurs (people using their non-certified home kitchens which are small and not FDA-complaint)

- Need for flexible, scalable production space

- Lack of distribution experience amongst growers and producers

- Growers losing large amounts of potential revenue from grade B products that could be used in other forms but today are usually wasted

- Cruise lines want to buy more local Bahamain products but cannot due to lack of FDA certification (food safety risk)

- There is often no connection between farmers and available distribution channels restricting growth and increasing dependence on imports.

- Inexperienced producers need training to enable business growth

The GROW Solution

- Provide an FDA-certified space for Bahamian farmers, artisans, and processors to manufacture, produce, & prepare on a commercial scale for distribution and export.

- GROW continues the process by providing a distribution channel, or consulting with clients on distribution options.

- Producers can rent storage space at the facility.

- Create additional revenue for producers by connecting them with manufacturers who can utilize their Grade B products and minimize food waste

- Training programs will offer high quality culinary and processing training that meets international standards of food handling and safety including food handlers certification.

- Offer programs to help small businesses expand their operations and reach commercial markets.

- GROW creates a community and will serve as a hub to connect farmers, producers and distributors

- GROW will reduce the barreir of entry for entrepreneurs by eliminating high costs associated iwth building out and managing a food business and bringing a product to market

- Opens new markets by faciliating exports of Bahamain products

- GROW makes everything simple by offering flexible payment structures and several payment options.

The GROW Advantage

- Only local FDA certified facility and certified trainers

- Wide variety of equipment available

- Very accessible and flexible, customers can pay by the hour, the day, or buy a membership

- Important regional connections and knowledgeable and experienced local owners

- Create new revenue streams by connecting growers, producers and distributors

- New solutions and processes to improve the welfare and wellbeing of individuals and communities in the region

- Expanding access to Bahamain producers both within the region and to export the Bahamain flavor to the U.S.

- Provide local businesses and manufacturers production space, packaging, and knowledge to present their products to local and international markets.

Competition

- There is little competition for GROW in the region. A single government run processing facility is not FDA certified and does not offer all of the necessary equipment or additional services GROW provides. Accessibility is difficult and consistency is an issue.

- The closest similar business is hundreds of miles away in the continental U.S. (Prep – Atlanta)

What we do

GROW is seeking to create a state-of-the-art internationally certified shared kitchen facility for farmers, processors, manufacturers, local food businesses, and chefs. The facility will be FDA Registered & Compliant “up to code”, fully equipped, and commercially designed to support the production and training needs of our local market. This facility will be used to grow and scale local businesses that require basic services and equipment to expand sales and distribution.

GROW will also provide external business services to assist small businesses and producers with market penetration and also provide the resources for distributorship and development of local Bahamian products. We will assist businesses with nutritional panels, labels, formulations, pricing, and introducing their products to local and international buyers.

We aim to improve the standard of Value-Added products produced and distributed in The Bahamas through training, cultural exchange, networking, access to opportunity and facilities. We will serve as an innovation hub for new ideas and provide individuals a space to explore concepts, products and ideas turning them into profitable operations by providing marketing, research, distribution and business support. The entity is spearheaded by two female entrepreneurs who are currently in the manufacturing and agro processing business and also teach entrepreneurship locally.

Currently there are many products that can be mass-produced locally at a central location and distributed throughout the islands and internationally. The manufacturing industry generates more economic activity than any other sector of the economy. For every dollar of domestic manufacturing value-added, another $3.60 of economic activity is generated elsewhere across the economy.

The founders want to raise the standards of production and explore export opportunities for our products and other locally made products. Our current market consists of farmers, local manufacturers, chefs & caterers, producers & entrepreneurs residing throughout the islands of The Bahamas. The current global crisis has led to the rise in home-based businesses and also a greater need for larger facilities and training. GROW will reduce the barrier of entry for many entrepreneurs by eliminating high costs associated with building out and managing a food business and bringing a product to market.

GROW is a FDA certified food processing facility and incubator space designed to assist food-based & product-based manufacturers with training, processing, packaging, and distribution of their products locally and internationally. Setting up and operating a food business is incredibly expensive in today’s market. With our service, we help to reduce entrepreneur’s barriers to entry by saving them build-out costs, as well as all the risks associated with permitting, construction, and development. This provides operators with a win-win alternative to help them expand their operations quickly. Our surveys reveal that bakers, caterers, and agricultural processors are the most common type of renters.

A list of all possible food business renters are as follows:

- Agricultural Products

- Ghost restaurants

- Allergen or Diet Specific Foods

- Beer, wine, and liquor

- Baked goods and pastry

- Catering or food service

- Chocolate, confectionery, and candy

- Consumer packaged goods

- Delivery-only restaurants or delivery operations of local restaurants Fermented food or beverages

- Food trucks or mobile cart vendors

- Marijuana product manufacturers & Research Facility (special licensing requirements apply)

- Meal service or box delivery programs

- Non-alcoholic beverages

- Pet foods

Many local artisans and manufacturers face challenges when trying to GROW their brands and bringing their products to market through a lack of resources, training, and funding. The founders have also faced these challenges with their businesses. Being able to create a space to manufacture, produce, package, and distribute Bahamian products locally and internationally in a regulated facility is a one-of-a-kind opportunity for many small businesses. Both owners have experience in local distribution and teaching and want to provide the shared opportunity and knowledge to more local brands.

In addition to shared kitchen space this facility will also assist in the services listed below:

- Incubation services and business classes Community and food safety classes

- Co-packing services

- Packaging solutions

- Food hubs

- On-site retail & Farmers Markets

- On-site & local Distribution

- Chef or product tastings

- Pop-up events and markets

- Workforce training programs

- Food access and security programs Community Supported Agriculture (CSA) and subscription programs

- Community dinners

- Special event rentals

- Photoshoots

- Film, TV, or YouTube cooking shows

Use of Proceeds

Financial Notes

|

FN# |

EXPLANATION |

|---|---|

|

REVENUE |

Revenue begins October 2021 allowing 3 month for leasehold improvements etc. |

|

1 |

Kitchen Space based on max capacity of 960 hours per month. (12hrs x $25ph x 4 users) |

|

2 |

Processing Kitchen based on max capacity of 960 hours per month. (12hrs x $20ph x 4 users) |

|

3 |

Storage based on max rental capacity of 32 units. (32 x rental cost) |

|

4 |

Members are offered exclusive deals and access to promotional activities for an annual fee of $250. |

|

5 |

School Rentals refer to the hosting of a Home Economics class on site @ $90 per class. School Tours refer to a two hour tour with max capacity of 90 students per day/1350 students per month considering a 15 day month. |

|

6 |

Training cost of local food based companies seeking to expand operations into commercial markets. |

|

7 |

Food testing to determine nutrition facts and values. |

|

8 |

Cruise Ship Tours based on a market capture of .01% of tourist arrivals pre-COVID (2019) |

|

9 |

Training programs offered to clients on a virtual platform. |

|

10 |

Packaging is calculated at 8% of the clients on a virtual platform. |

|

DIRECT COST |

|

|

11 |

Employee Training 3% of Salaries and Wages |

|

GENERAL NOTES |

|

|

|

Facility Maintenance 15% of overall revenue. |

|

Employee Related Expenses related to NIB contributions made on behalf of employees. |

Use of Funds

|

$ |

DESCRIPTION |

|---|---|

|

101,625.00 |

Kitchen Equipment |

|

70,000.00 |

Testing Lab Equipment |

|

8,000.00 |

Company Vehicle |

|

650,000.00 |

Building Purchase |

|

55,000 |

Leasehold Improvements |

|

25,000.00 |

Solar System |

|

90,000.00 |

Contingency |

|

999,625 |

Total |

|

$1,000,000.00 |

Funding Ask |

Business Model

While we do not anticipate that the rental fees will cover the entire costs of the program as we will continue serving self starter businesses, it will contribute a reasonable amount. Understanding the importance of long-term sustainability, we will constantly develop and implement plans to diversify our revenue streams. We are confident we will be able to increase our programmatic and organizational sustainability through a combination of strategies:

- Rental fees for FDA-certified kitchen space

- Registration fees

- Rental Space- We will host special events in order to bring in additional revenues. With the ideal location additional space can be used as an event venue to host food-centric events and training

- classrooms.

- Rental Storage (Dry & Cold Storage)

- Hosting Incubator Classes – such as facilitating ServSafe licensing classes, etc.

- Equipment rental

- Packaging Services

- Retail Shop

- Wholesale Distribution

Vision

Our vision is to revolutionize the agriculture industry in the Bahamas by creating opportunities and growth for farmers, artisans, and processors. Our mission is to provide a safe space for Bahamians to manufacture, produce, & prepare on a commercial scale for distribution and export.

- GROW’s founders envision becoming the regional hub for food production and distribution in the Bahamas.

- GROW’s ability to connect farmers with producers and distributors, and its strong regional connections, are likely to result in GROW becoming the “go to” source for everything food-related in the region.

- It can be both a very profitable business and a source of information and training that lifts up the entire region and dramatically improves its self-sufficiency.

Why Invest Now

- The Bahamas has long been a popular visitor destination and favored stop for cruise lines. Recent changes now include disembarkation ports in the Bahamas, greatly extending the time passengers will spend in the Bahamas.

- The cruise lines have committed to spending $2M per year on Bahamian products but they must be certified as safe, a perfect match for GROW’s offerings.

- The Bahamas is committed to reducing the $9B in food imports per year and becoming a more self-sustaining region

The Team

Regina, Owner of Firehouse Spices has been operating for 6 years as a wholesaler and a retailer. Distributing locally to restaurants and stores, as of recently obtaining placement in the US Distribution market, with products being sold in New York and featured on the US Embassy, Washington DC portal representing The Bahamas. Regina is also a facilitator of the AWE program hosted by the US Embassy & SBDC, giving her the tools to achieve company goals. Regina has also kept a close working relationship with US Universities geared toward food production and development. Her network with the University of Virginia and Cornell University, provides direct contact with their food science departments and innovation centers.

Kentisha, Owner of Pop Stop Gourmet Popsicles has been in operation since October 2015, wholesaling and retailing to local markets. Pop Stop has expanded to Solomon’s Fresh Market, Bahamar & Atlantis Resorts creating valuable distribution networks. Kentisha has also taught entrepreneurship at BTVI & Queen’s College CFE for 5 years consecutively.

Both owners being educators gives them the ability to facilitate the training of potential clients and or members and have the access to finding out what the local challenges are for small product & manufacturing businesses.

Our current structure will place Regina taking on the roles to manage these various sections Processing, Corporate Relations, Sourcing, Business/Grant Writing & Applications. Kentisha will take on the roles of Client Acquisitions, Packaging Sourcing, Training Outlines, Facilities Management, Sales & Acquisitions & Marketing & Distribution. Our goal is to step back from private production and focus on enriching, and strengthening this sector through our connections and training opportunities. Both will present a shared focus towards training and export. Using this management style will allow the owners to spread out responsibilities and focus on areas they excel in. We intend to employ additional persons in the areas of Maintenance, Product Development , Administration and Processing. Our initial plan includes nine (9) employees and with the full build out we intend to double this number.

- Executive Administrator – will serve as a receptionist at the front desk and will act as a first point of contact for many clients. This person will manage Kitchen Appointments, & Equipment Rentals and overall upkeep of the reception area. This person will also process point of sale for the facility retail centers.

- Facilities & Maintenance Manager – This person will oversee all operations in the facility while on staff. They will be responsible for general upkeep of all kitchens and equipment rentals.

- Research & Development Manager – Manages and directs the research and development of programs to meet organisational goals as well as assists in the development of new products and offerings.

- Chief Executive Officer (CEO) – This position will be held by Regina Smith. This role will be responsible for the layout and program opportunity management. Regina will be responsible for Business & Grant Writing Applications. Due to her experience with building an Export network and requirements she will be tasked with the build out of the export program. Regina also has immense knowledge in the processing of various local items and will spearhead the management of the processing space and product innovation.

- Chief Operations Officer (COO) – This position will be held by Kentisha who will head the training facilities, packaging facilities, and distribution networks. Kentisha will also assist with facilities management.

- Accounting Manager – Supervise, monitor and evaluate all day-to-day accounting activities.

Part Time Employees

- Sales Person – This is a commission based position. Employees will be hired to promote the local sales and GROWth of our local distribution network. Responsible for taking orders , and monitoring the quality and quantity of our client products in local stores.

- Tour Guide – a commission based position to facilitate incoming cruise ship and school tours.

- Maintenance Person – An on call handyman to assist with plant and facility operations.

- Facility Aid – This Individual is responsible for general cleanliness and upkeep of public spaces and thoroughfares.

We will employ external companies for overall sanitizing and deep cleaning of the facility. Until we are fully operational 24/7 we will utilize an RFID program to secure spaces.

Our Objectives

1) To provide a safe & regulated space for food-based entrepreneurs to create at an exceptional quality & FDA standards

2) Train and facilitate local producers to showcase their products and services on a local and international platform.

3) To reduce the barriers of entry to small food and manufacturer businesses by providing basic machinery, space, and support for small businesses.

4) To create focus towards women by providing the necessary training, resources, and knowledge to scale and expand their businesses through workshops and collaboration.

5) To create an innovative hub of manufacturers and artisans utilizing a shared processing facility.

6) To support and promote products that support local producers in the development of their communities.

7) To access external funding & support from national and multinational agencies to support programs, certifications, training, and licensing.

Industry & Market Analysis

During the pandemic, many persons launched food businesses as a means to provide economic stability during these times. The challenge many are now facing is the outgrowth of their kitchens and the need to expand. Currently, there are two (2) processing spaces in New Providence; Gladstone Road Food Lab & BAIC Food Lab. However, the challenges with both facilities are access to equipment, electrical issues, scheduling, and lack of machinery to bring products to market.

This has driven many to resort to entrepreneurship, many being food based companies. The rise in ghost kitchens and at home manufacturers has brought the big question of where everything is being produced. Many businesses have realized the need to grow and scale through export. Currently, there are limited avenues for local manufacturers to expand. One of the key requirements to exporting food based products is manufacturing in a FDA certified space. After production or harvest, there is a need for dry and frozen storage space. Especially in the terms of frozen storage, many frozen purveyors normally acquire multiple chest freezers and pay high electricity prices and wastage due to power outages. Bahamian cuisine is bahamian culture, this gives us an avenue to showcase this culture through tours (Cruiseship and local) and training sessions. Another component of scaling and export is food testing, there is a need for a multifaceted food & nutrition testing lab. Our customers will be small to medium-sized manufacturers, farmers, local grocers, and international distributors. There have been many small-scale programs geared towards manufacturing, but none on the scale at which we are proposing. We will partner with out-island farmers in this business model as well, our goal is to utilize the relationships we’ve built over the years to purchase from and empower these farmers ensuring they are equipped with the necessary tools and guidelines to contribute to the manufacturing ecosystem. This ultimately makes a direct contribution to food security as wastage is mitigated. To date, we have begun working with Twelve (12) farmers based in North Andros with acreages totaling 140+ acres.

Packing houses for many years have not been able to purchase all of the produce grown on the various islands. This has led to wastage of crops, the facility will provide an avenue for farmers to process and directly connect to clients who may need their goods. Post Harvest Production plays a very important role in crop production as it determines the final product’s quality. If the crops are graded to be in good condition after postharvest they can be sold as fresh consumption. On the other hand, if the crops are graded as damaged, they become the inputs for processed food products. The technology we will utilize will be for preservation, quality control, processing, storage, and distribution of many agricultural products. These technologies will make sure that products will meet the food and nutritional needs of the consumers.

In terms of storage there are a few challenges that exist in this realm such as high electricity costs, and cost of rental space. Many manufacturers are limited to space for their finished products. After scaling up there presents an increased need for storage space. The cost of storing frozen products is typically done by purchasing chest freezers which can be expensive in the cost of electricity, space and potential wastage due to power outages. These realities have stifled the industry and small-scale manufacturers. Therefore, we aim to work with local manufacturers to increase capacity, and agitate for lower tariffs, fees, and rates; this will ensure sustainability and the ability to explore other international markets with a guaranteed consistent production.

Our main kitchen will be the most requested kitchen by many Chefs and caterers who struggle to find adequate spaces to prepare for their markets or events. Ghost kitchens that have started and outgrown their space and will need this space to process their restaurant quality food without the high cost of restaurant set up.

The manufacturing, processing and culinary industries can create jobs on multiple levels in the economy. Although many do not need direct capital most would benefit from other resources. Escalating unemployment numbers has proven that we must implement programs that help to alleviate the economic burden, and implement strategies for sustainability and growth in the agriculture and industrial sectors.

Outside of business planning training , there is a local need for processing and manufacturing training, to ensure the processes are done adequately or securely. This training can give small businesses the knowledge to scale their processing business.

Many cruise ship ports offer factory tours, there is a limited number of factory tours in nassau and this facility can provide the option of viewing tours along with cooking tours.

With a limited amount of locations where you can access 100% bahamian made products in the downtown area. This facility can serve as a retail outlet for 100% locally made products made from the manufactured and processed items in house

Implementation & Marketing

We will begin our training sessions, with the initial roll out of our Product Distribution class. This class will train and prepare local entrepreneurs to make their products viable for foodstore and product shelves. Training will encompass a large range of essential topics such as pricing, sourcing, packaging, etc. We have received a commitment from 15 local vendors who are ready and willing to participate in our training program and would like to utilize our future services. This class would be a part of the initial marketing strategy of the company to raise awareness of our programs and gauge the market needs.

After discussions with the company cloudpro, we intend to use this company for our initial marketing campaign, and branding. Marketing and Promotional material will be designed specifically for our targeted groupings with messaging tailored for persons along our value chain including processors and manufactures as well as Cruise visitors.

Being the first FDA regulated facility in The Bahamas adds significant value to the business and opens the possibilities for culinary entrepreneurs by advertising to all major entrepreneurship training programs, schools, the SBDC and local funding institutions. One major feature will be the multipurpose website that will allow potential clients to learn about the services offered, participate in a virtual tour and book appointments. GROW will also rely on the use of digital and social media platforms to capture our markets. We plan to work hand in hand with the SBDC and other incubator & training programs such as the One Eleuthera Foundation, to enhance the training and opportunities for our members. Partnering with these organizations can also provide agriculture and food entrepreneurs the knowledge to process and develop to ensure client success if possible.

Site, Organization & Services

We aim to design a state of the art Prep Kitchen and Manufacturing Lab. Our goal is to acquire the land and building and provide the physical kitchen infrastructure, training opportunities, and business mentoring needed to support, incubate, and educate present and future local food and artisanal business entrepreneurs. The cost of leased space is a burden that is difficult for an incubator program to manage, even when the incubator is operating at full capacity.The required space will be approximately 4,000 to 5,000 sq ft inclusive of kitchen and other key operational areas. This will be the first shared-use commercial kitchen in The Bahamas that is FDA Registered & Compliant, up to code, fully equipped, and commercially set up to support the production and training needs of our local market.

The design includes the shared kitchen spaces along with designated workstations and rooms to allow up to five manufacturers concurrently. There will be a Preparation Room, Dehydration Corner, Bakers Station, two (2) Kitchen areas, Packaging Room & Canning Room. The facility will be equipped with a retail space, reception area as well as loading and receiving docks as well.

These rooms and stations cater to the most common industry niches eg. fruit and vegetable pulping, canning, dehydration & grinding. They will also serve as a receiving point for fresh produce as well . The Kitchen will function in post-harvest processing, packaging and storage and a distribution site. This will be a multimedia teaching and learning space for the innovative development and preparation of products originating from our members. It will serve as a place where people with ideas for new food products can get help bringing them to market. GROW will facilitate developing nutritional panels, labels, formulations as well as introducing their products to store owners and buyers. Sometimes dealing with various agencies such as the FDA or health departments can be daunting. Our facility will be inspected and surpass world class production standards.

In addition to the facility being used by local manufacturers, we will also process crops for sale and consumption. These include: Potatoes, Avocados, Mixed vegetables (broccoli & carrots), and Pumpkin

Equipment & Machinery

We have created a phased approach to the design and layout of the facility as well as the equipment needs. We will explore portable options and will opt to purchase new equipment along with warranties for more valuable assets. We have decided on a fluid flow of our kitchen spaces and will utilize moveable stations and partitions to ensure maximum capacity and processing outputs.

We will utilize a booking software to manage services such as reservations, inventory tracking, client charges and equipment rental .

We have opted to design a more ‘Green Kitchen” to save money in the long run. Areas such as design, electrical, plumbing, and equipment will all have sustainability elements in mind, from energy star equipment and solar power to motion detected lights.

Rental Equipment

We will offer a large range of rental equipment for our clients. The equipment will be offered in an A La Carte style and on a first come first serve basis. These will range from large pots , immersion blenders to dehydrators. In our first phase we intend to acquire the most commonly requested equipment in our surveys. These will be rented out to clients on a time slot basis of (4 hours per client). The clients are allowed to book more than 1 slot if it is needed and available. Late returns will be charged a fee of$25 per hour after the 1st 10 minute delay. Equipment Rentals will be managed by Admin Staff and the Facilities Manager with a barcode system and rental app.

Shared Storage Facilities

Clients have the opportunity to rent cold storage space by their crate size. Members will have a reduced rate on cold storage space. Dry rentals will also be offered allowing clients to secure their inventory at our facility easing the burden of transport to and fro.

Our storage bins come in a variety of sizes and colors for cold and dry usage. They are also equipped with lock boxes that can be assigned to members upon request. The bins are 10”19”, 29” and Pallet Size. This allows for ease of storage and inventory keeping for our members, they won’t have to haul their raw materials to and from the facility and can trust that it will be safely secured.

Onsite Retail & Shared Distribution Network

GROW is currently establishing a local and international distribution network to facilitate the local demand for Bahamian products. We intend to present all products from our clients to our distributors on our network. We have an ever GROWing product list with Bahamian vendors that have unique and one of a kind products that can compete with international brands on quality.

To date, we have clients such as Albany and Fresh Market on our distribution networks with hopes to expand to more than 100 stores and sellers by the third quarter of 2022.

We are currently exploring international buyers to distribute our products internationally. With Firehouse Spices being sold throughout the United States, we have already begun the process of exploring costs and avenues to export.

We intend to export our frozen packaged items via shipping container to the US and Caribbean for export. There is a demand for Bahamian made products by the Caribbean diaspora and persons wanting that familiar taste of The Bahamas especially during this time of limited travel.

We will require a small distribution fee that will be applied to wholesale costs for our clients to offset the cost of sales and distribution as well as promotion at regional and international trade shows. This model allows us to actively push as agents showcasing brands we can vouch for, brands that have been vetted based on FDA standards and brands that have followed strict production guidelines

Additional Services

Programs

Our training programs are set to offer high-quality culinary & processing training that meets international standards of Food Handling & Safety. We will also provide our manufacturers and participants Food Handlers Certification administered by our site Certified Proctor. This Certificate can also be completed virtually, to ensure persons throughout the country can attain the necessary food handling knowledge and certification. Participants will also be trained in international standard packaging requirements. Participants will be able to meet challenges with a systematic approach to quality food production, as per food manufacturing services.

Small Business Training

We have designed a list of programs to directly address the current knowledge gaps locally. Specifically for local product and food based companies that want to expand their operations to reach commercial markets. Participants enrolled in the program will go through an intense bootcamp exercise specifically designed to get their products ready for distribution. The initial program will consist of guest lecturers, industry experts and will be led by trained facilitators. Our goal is to ensure quality products through packaging, pricing and promotions. We hope to work with the Ministry of Health & SBDC, Access Accelerator Program to facilitate many of our incubator services and onsite mentorship. Training Topics include but are not limited to:

Product Packaging Requirements

Product Catalog

SKU & Bar Codes

Wholesale and Suggested Retail Prices

Distribution Marketing Strategies

Sales Pitch

Purchase Order Inventory & Payment Terms

Accounting Software/ Bookkeeping

Branding / Photoshoot

Label Review

FDA Standard

ServSafe® Food Handler*

Safety & Foodhandlers

Health & Nutrition

Specialty Classes

*ServSafe® Food Handler- We will offer the ServSafe® Food Handler Course virtually and in person which makes it convenient for our clients and new food producers.

About the ServSafe® Food Handler Course/Guide: • Course Length: Approximately two hours. • Assessment Length: A 40-question, non-proctored test with no time limit. • Language: English • Certificate: Included with the guide to be signed by instructor upon successful completion of program.

Specialty Classes- Include but are not limited to Jam Making, Ice Cream Making , Seasonal Chef Curated Classes (E.g Christmas Ham & Turkey, Recipe Based Classes) Quickbooks for your business. These classes will be available to our members and non-members. Hosting these training programs at our facility will increase the overall kitchen and business knowledge of all of our clients guaranteeing their success and also ours. These classes increase the quality and standard of production, on and off of our compound.

Ownership Structure & Rights of Securities

Financial Plan

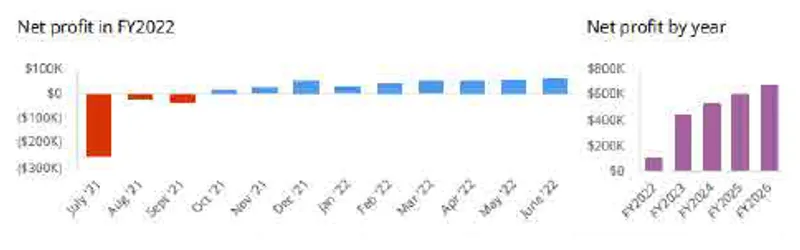

Based on the size of our market and our defined market area, our sales projections for the first year are $900,000.00 based on the final forecast. We project a growth rate of 7-10% for the first five years of operation. At start up we will have seven trained staff members to provide assistance in the ration, production and distribution areas. To date, we have received commitments from over 40 clients and plan to aggressively build our client base through newspaper, website, social media, and email advertising. We have projected an initial start-up capital injection of $1 million ($1,000,000.00) inclusive of the cost of equipment and administrative expenses. We have also included a Building Budget that allows for the purchase of a building as well as the necessary Leasehold Improvements. We are seeking investors that care about the future of entrepreneurs, farmers, and small food-based businesses and manufacturers. Investing in the future of GROW is, ultimately, investing in the future of all farmers, processors, producers, manufacturers, and food-based businesses.

Grow

FY2022-FY2026 Forecast

Grow Processing

Generated June 11, 2021

Projected Profit & Loss

|

Projected Profit & Loss |

FY2022 |

FY2023 |

FY2024 |

FY2025 |

FY2026 |

|---|---|---|---|---|---|

|

Revenue Kitchen Space (FN1) Processing Kitchen (FN2) Food Testing (FN7) Frozen Storage (FN3) Cold Storage (FN3) Dry Storage (FN3) Membership Fees (FN4) School Rentals (FN5) School Tours (FN5) Training (FN6) Virtual Training (FN9) Cruise Ship Tours (FN8) |

$908,385 $183,375 $152,500 $37,100 $46,420 $51,920 $12,870 $49,000 $20,250 $130,500 $47,250 $71,250 $105,950 |

$1,146,100 $267,550 $217,100 $40,800 $60,720 $65,780 $16,335 $54,000 $26,280 $155,925 $52,050 $76,200 $113,360 |

$1,233,775 $285,050 $232,300 $44,500 $66,220 $71,720 $17,820 $58,750 $28,620 $170,100 $56,700 $81,225 $120,770 |

$1,323,200 $302,550 $247,500 $48,200 $71,720 $77,880 $19,305 $63,750 $31,050 $184,275 $61,500 $86,250 $129,220 |

$1,411,865 $320,075 $262,700 $51,900 $77,220 $83,820 $20,790 $68,500 $33,390 $198,450 $66,150 $91,200 $137,670 |

|

Direct Costs Packaging (FN10) Salaries & Wages Gross Margin Operating Expenses Salaries & Wages |

$202,048 $12,200 $98,668 $706,337 $526,083 $199,587 |

$150,112 $17,368 $106,554 $995,988 $469,962 $230,000 |

$154,645 $18,584 $109,504 $995,988 $476,535 $230,000 |

$159,443 $19,800 $112,700 $1,163,757 $483,213 $230,000 |

$164,358 $21,016 $115,993 $1,247,507 $489,848 $230,000 |

|

Employee Related Expenses Legal Fees Liability Insurance Building Insurance Equipment Insurance Vehicle Insurance & Licensing Vehicle Wrap Vehicle Fuel Management Software FDA Registration Fees Electricity Utilities (Water) Internet & Phone Marketing Repairs & Maintenance (Facility) Repairs & Maintenance (Vehicle) Storage Furnishings Storage Equipment Janitorial & Sanitization Office Supplies Website Developmeny & Maintenance Garbage Removal Extermination Services Propane Gas Sanitization & Deep Cleaning Services Security Security Equipment (Cameras, Monitoring) Access Control Consultancy Fees Financing Fee |

$39,917 $2,000 $3,000 $1,500 $1,000 $700 $4,000 $1,100 $11,119 $1,500 $23,000 $1,332 $2,400 $27,252 $27,229 $666 $644 $9,169 $2,719 $4,500 $9,650 $1,500 $1,000 $3,600 $6,000 $12,000 $3,600 $8,400 $16,000 $100,000 |

$46,000 $350 $3,072 $1,536 $1,024 £700

$1,200 $6,709 $1,500 $27,600 $1,600 $2,880 $34,383 $34,383 $800 $816 $13,377 $3,030 $6,000 $1,800 $1,800 $1,000 $3,600 $6,000 $14,400 $3,600 $4,800 $16,000

|

$46,000 $350 $3,144 $1,572 $1,048 £700

$1,200 $6,870 $1,500 $27,600 $1,600 $2,880 $37,013 $37,013 $800 $891 $14,253 $3,101 $6,000 $1,800 $1,800 $1,000 $3,600 $6,000 $14,400 $3,600 $4,800 $16,000

|

$46,000 $350 $3,216 $1,608 $1,072 £700

$1,200 $7,031 $1,500 $27,600 $1,600 $2,880 $39,696 $39,696 $800 $966 $15,127 $3,172 $6,000 $1,800 $1,800 $1,000 $3,600 $6,000 $14,400 $3,600 $4,800 $16,000

|

$46,000 $350 $3,288 $1,644 $1,096 £700

$1,200 $7,192 $1,500 $27,600 $1,600 $2,880 $42,356 $42,356 $800 $1,039 $16,004 $3,243 $6,000 $1,800 $1,800 $1,000 $3,600 $6,000 $14,400 $3,600 $4,800 $16,000

|

|

Operating Income Income Taxes Depreciation & Amortization Total Expenses Net Profit Net Profit % |

$180,254 $0 $72,290 $800,421 $107,964 12% |

$526,027 $0 $72,290 $692,363 $453,737 40% |

$602,595 $0 $72,289 $703,469 $530,306 43% |

$680,543 $0 $72,290 $714,947 $608,253 46% |

$757,658 $0 $72,290 $726,496 $685,369 49% |

Projected Balance Sheet

|

Projected Balance Sheet |

FY2022 |

FY2023 |

FY2024 |

FY2025 |

FY2026 |

|---|---|---|---|---|---|

|

Assets Current Assets Long-Term Assets |

$1,107,964 $270,629 $837,335 |

$1,561,701 $769,656 $765,045 |

$2,092,007 $1,399,251 $629,756 |

$2,700,260 $2,079,794 $620,466 |

$3,385,629 $2,837,452 $548,176 |

|

Liabilities & Equity Liabilities Equity |

$1,107,964 $0 $1,107,964 |

$1,107,964 $0 $1,107,964 |

$2,092,007 $0 $2,092,007 |

$2,700,260 $0 $2,700,260 |

$3,385,629 $0 $3,385,629 |

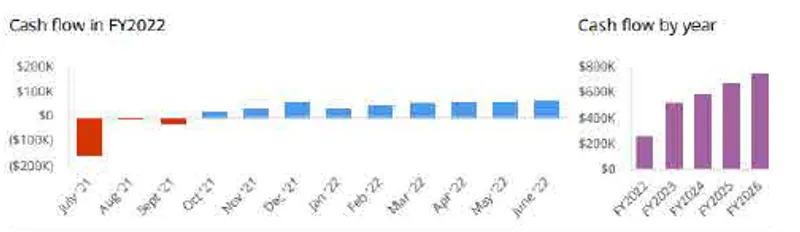

Projected Cash Flow

|

Projected Cash Flow |

FY2022 |

FY2023 |

FY2024 |

FY2025 |

FY2026 |

|---|---|---|---|---|---|

|

Net Cash from Operations Net Profit |

$180,254 $107,964 |

$526,027 $453,737 |

$602,595 $530,306 |

$680,543 $608,253 |

$757,659 $685,369 |

|

Net Cash from Investing Asset Purchased or Sold |

($909,625) ($909,625) |

||||

|

Net Cash from Financing Investments Received |

$1,000,000 $1,000,000 |

|

|||

|

Cash at Beginning of Period Net Change in Cash Cash at End of Period |

$0 $270,629 $270,629 |

$270,629 $526,027 $796,656 |

$796,656 $602,595 $1,399,251 |

$1,399,251 $680,543 $2,079,794 |

$2,079,794 $757,659 $2,837,452 |

Assets

|

Assets |

FY2022 |

FY2023 |

FY2024 |

FY2025 |

FY2026 |

|---|---|---|---|---|---|

|

Long-Tern Assets Stoves, Microwaves & Ovens |

$837,335 $30,564 |

$765,045 $22,923 |

$692,756 $15,282 |

$620,466 $7,641 |

$548,176 $0 |

Exit Strategy

1) Review Financials

2) Consider options

3) Speak with investors

4) Consider new leadership

5) Inform employee

6) Inform customers

Upon review of the business’ financials, if the business is facing critical reductions in revenue and no immediate path to recovery, the following options will be considered:

Potential Merger

Sale

Public Offering

Liquidation

Risks & Disclosures

Coming Soon

AN OFFERING STATEMENT REGARDING THIS OFFERING HAS BEEN FILED WITH THE SEC. THE SEC HAS QUALIFIED THAT OFFERING STATEMENT, WHICH ONLY MEANS THAT THE COMPANY MAY MAKE SALES OF THE SECURITIES DESCRIBED BY THE OFFERING STATEMENT. IT DOES NOT MEAN THAT THE SEC HAS APPROVED, PASSED UPON THE MERITS OR PASSED UPON THE ACCURACY OR COMPLETENESS OF THE INFORMATION IN THE OFFERING STATEMENT.

THE OFFERING MATERIALS MAY CONTAIN FORWARD-LOOKING STATEMENTS AND INFORMATION RELATING TO, AMONG OTHER THINGS, THE COMPANY, ITS BUSINESS PLAN AND STRATEGY, AND ITS INDUSTRY. THESE FORWARD-LOOKING STATEMENTS ARE BASED ON THE BELIEFS OF, ASSUMPTIONS MADE BY, AND INFORMATION CURRENTLY AVAILABLE TO THE COMPANY’S MANAGEMENT. WHEN USED IN THE OFFERING MATERIALS, THE WORDS “ESTIMATE,” “PROJECT,” “BELIEVE,” “ANTICIPATE,” “INTEND,” “EXPECT” AND SIMILAR EXPRESSIONS ARE INTENDED TO IDENTIFY FORWARD-LOOKING STATEMENTS, WHICH CONSTITUTE FORWARD LOOKING STATEMENTS. THESE STATEMENTS REFLECT MANAGEMENT’S CURRENT VIEWS WITH RESPECT TO FUTURE EVENTS AND ARE SUBJECT TO RISKS AND UNCERTAINTIES THAT COULD CAUSE THE COMPANY’S ACTUAL RESULTS TO DIFFER MATERIALLY FROM THOSE CONTAINED IN THE FORWARD-LOOKING STATEMENTS. INVESTORS ARE CAUTIONED NOT TO PLACE UNDUE RELIANCE ON THESE FORWARD-LOOKING STATEMENTS, WHICH SPEAK ONLY AS OF THE DATE ON WHICH THEY ARE MADE. THE COMPANY DOES NOT UNDERTAKE ANY OBLIGATION TO REVISE OR UPDATE THESE FORWARD-LOOKING STATEMENTS TO REFLECT EVENTS OR CIRCUMSTANCES AFTER SUCH DATE OR TO REFLECT THE OCCURRENCE OF UNANTICIPATED EVENTS.

WHILE THE COMPANY HAS SIGNED A QUOTATION AGREEMENT TO TRADE THE SECURITIES OFFERED ON ARAWAKX SECONDARY’S NEW ALTERNATIVE TRADING SYSTEM (THE “ATS”), A COMPANY WHICH INTENDS TO BE QUOTED ON THE MARKETPLACE WILL BE SUBJECT TO CERTAIN REQUIREMENTS WHICH THE COMPANY MAY OR MAY NOT BE ABLE TO SATISFY IN A TIMELY MANNER. EVEN IF A COMPANY IS QUALIFIED TO QUOTE ITS SECURITIES ON THE MARKET, THERE IS NO GUARANTEE AN ACTIVE TRADING MARKET FOR THE SECURITIES WILL EVER DEVELOP, OR IF DEVELOPED, BE MAINTAINED. YOU SHOULD ASSUME THAT YOU MAY NOT BE ABLE TO LIQUIDATE YOUR INVESTMENT FOR SOME TIME OR BE ABLE TO PLEDGE THESE SHARES AS COLLATERAL.

View our Offering Documents

You must register or log in before you can view this page.

Meet the GROW - The Food Lab team

Regina Smith

Co-Owner/CEO

Owner of Firehouse Spices has been operating for 6 years as a wholesaler and a retailer. Distributing locally to restaurants and stores, as of recently obtaining placement in the US Distribution market, with products being sold in New York and featured on the US Embassy, Washington DC portal representing The Bahamas.

Kentisha Ward

Co-Owner/CEO

Owner of Pop Stop Gourmet Popsicles has been in operation since October 2015, wholesaling and retailing to local markets. Pop Stop has expanded to Solomon’s Fresh Market, Bahamar & Atlantis Resorts creating valuable distribution networks. Kentisha has also taught entrepreneurship at BTVI & Queen’s College CFE for 5 years consecutively.

Advisors

Advisory Board

In an effort to ensure success in the management and operation of the business, we have selected key individuals as a part of our advisory board. Their expertise range from fundraising & strategic development to legal and financial advisory.

|

|

Mrs. Vanessa Haley - Benjamin With over 20 years of experience in conservation and nonprofit executive leadership, Mrs. Vanessa Haley-Benjamin once served as the Chief Scientist of the Baha Mar resort, CEO of Save The Bays, the Director of Science and Policy at The Bahamas National Trust and is currently the Executive Director and Chief Scientist at Bahamas Sportfishing Conservation Association. She served on the board of the Baha Mar Resort Foundation and currently sits on the Scientific Seafood Advisory Board for Good Food Institute. Having raised over $3 million to support local conservation efforts, Mrs. Haley-Benjamin possesses skills in nonprofit management for the 21st century with specific experience and training in strategic planning, fundraising, financial analysis, and program evaluation for nonprofits. |

|

|

Ms. Sumayyah Cargill Sumayyah Cargill is a Canadian educated industrial engineer who is focused on systemic improvement and change management in the business environment. Following employment abroad as an analyst and technical writer she returned to the Bahamas and worked as The Communications Specialist for the Public Financial Management and Performance Monitoring Reform Project under The Ministry of Finance. She is currently the Unit Head of Strategic Development and Initiatives at the Bahamas Development Bank where she is focused on integrating Sustainable Development Frameworks into daily operations for the Bank and generating projects that combine creative financing, technical assistance and policy advocacy for innovation in the colored economies. |

|

Mrs. Zeleka Knowles Mrs. Knowles is an international civil servant with nearly fifteen years of experience in the non profit sector working in Africa, Europe, Asia and most recently the Caribbean. As the Program Associate with Templeton World Charity Foundation, she supports the Global Innovations for Character Development and Big Questions in Classrooms initiatives. Additionally, she contributes to the Foundation’s communications and storytelling, particularly through social media. |

|

Retired Magistrate Mrs. Jannet Bullard After serving 25 years as a Banker at Barclays Bank Intl, Jannet Bullard was called to The Bar of England & Wales July 25th, 2002. Prior to joining the Supreme Court Rt. Magistrate Bullard articled with Davis & Co. In September 2007 she was enrolled as an attorney to the Supreme Court of The Bahamas and became the first resident stipendiary and circuit magistrate in George Town Exuma, where she held that position for five (5) years. Her expertise ranges from banking to all legal matters including contracts, disputes and litigation. She is currently an attorney at law but has decided to take a short sabbatical. |

|

Mrs. Janet Johnson Janet Johnson is a Tourism veteran with 40+ years in Tourism marketing under her belt. Her career has afforded the privilege of foreign postings in the UK and the US representing the Ministry of Tourism, she has held various leadership positions here at home and now serves as the CEO/Executive Director for the Tourism Development Corporation.

|

Key Customers & Partners

Our Customers

Food safety is top priority at GROW & while we acknowledge that our customers will have varying needs the overarching goal for each one is to produce goods that are safe and packaged to maintain quality and freshness. In addition to food preparation our customers needs include:

Farmers – Farmers with excess produce can use this facility to turn their raw material into finished goods or offer their goods for sale to the local vendors or client base.

Manufacturers – The common challenge amongst local manufacturers is the lack of space and storage to produce and store their finished products. We will provide a space to scale their production and house their finished products.

Processors – Many of the common processors use common machinery, our facilities will house the common types of machinery to address the local market such as dehydrators & oil pressers to name a few.

Ghost Kitchens – The rise in ghost kitchens. A ghost kitchen is a restaurant you may see online, with no physical location. This growing market has created a demand for clean and safe kitchen space.

Chef’s & Caterers – This allows local chefs to host private events and functions without having to resort to small home kitchens or major hotels. Our top-of-the-line facilities will also be available for photoshoots and videos.

Teachers & Training Organizations – Our training classroom is perfect to host food preparation and safety classes. Also if chefs want to host specialty training classes they can be hosted here.